- industrial air compressor

- desiccant compressed air dryer

- diesel air compressor

- large vacuum pump

- oil free piston air compressor

- oil free screw air compressor

- oil free scroll air compressor

- pm vsd dual stage screw air compressor

- pm vsd single stage screw air compressor

- refrigerated air dryer

- screw blower

- single stage double screw air compressor

- two stage double screw air compressor

- ultra high pressure air compressor

coal washing machine chain for your mines and coal yards

Coal washer chain is used as mechanical conveying equipment in coal washing equipment, and its main function is to realize continuous vertical lifting of powdery, granular and small pieces of materials.

Description

Coal Washer Elevator Chain is a specialized chain designed for use in coal washing equipment, enabling continuous vertical lifting of materials with high reliability and efficiency. According to the running speed of the hopper, coal washer elevator chains are available in three unloading forms: centrifugal unloading, gravity unloading, and mixed unloading—each suitable for different types of conveyed materials.

Principle

The elevator chain operates through a fixed device, ensuring the continuous lifting of materials. Centrifugal unloading (fast bucket speed) is ideal for powders, granules, and small abrasive pieces; gravity unloading (slow bucket speed) suits larger, heavier, and more abrasive materials; mixed unloading combines both methods for flexible operation.

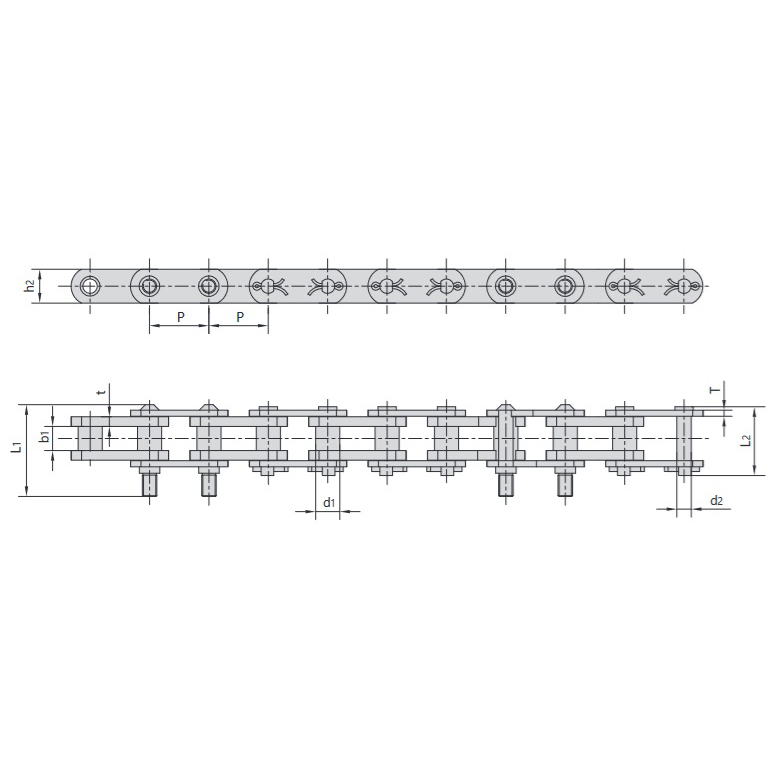

Structure

- Ring Chain: Simple structure, firm connection with the hopper, minimal wear, but heavier weight.

- Plate Chain: Sturdy and lightweight, suitable for large volume lifting; however, joints may experience wear over time.

- Tape: Simple design, less suitable for abrasive materials.

The transmission system typically includes rubber belts mounted on drive rollers and redirection rollers, or parallel transmission chains with sprockets for chain-driven systems. The elevator assembly includes an upper shell, active shaft, reducer, coupling, motor, and customizable central shell sections to accommodate different lifting heights.

Features & Benefits

- Wide Lifting Range: Capable of handling a variety of materials and lifting needs.

- Good Operational Reliability: Designed for stable, long-term operation with minimal downtime.

- Long Service Life: Robust construction and material selection ensure durability in demanding coal washing environments.

- Versatile Structure: Choice of ring chain, plate chain, or tape to meet specific material and operational requirements.

- Efficient Material Handling: Hoppers scoop, lift, and discharge material smoothly and reliably.

Applications

- Coal washing equipment

- Material handling in mining and industrial processing

- Vertical lifting systems for abrasive or heavy materials

Coal Washer Elevator Chains are essential for continuous, efficient, and reliable vertical lifting in coal washing facilities, offering broad adaptability, robust performance, and long-lasting durability.

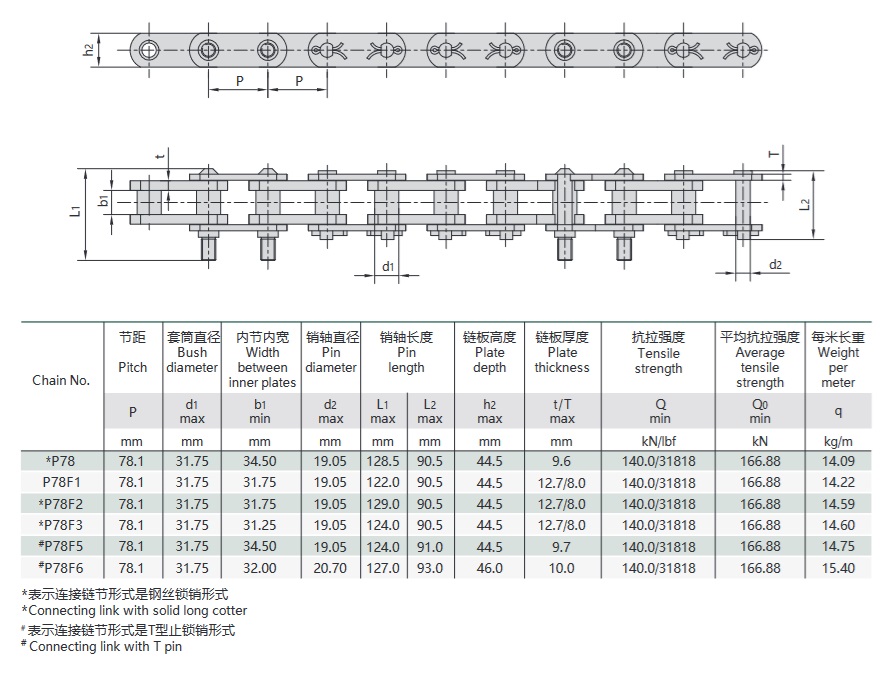

Technical Parameters

coal washing machine chain technical table

English

English  Français

Français  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  Türkçe

Türkçe  Svenska

Svenska  Polski

Polski  Română

Română  Latviešu

Latviešu  한국어

한국어  Русский

Русский  Español

Español  Deutsch

Deutsch  Українська

Українська  Português

Português  العربية

العربية  Indonesian

Indonesian  Čeština

Čeština  Suomi

Suomi  Eesti

Eesti  Български

Български  Dansk

Dansk  Lietuvių

Lietuvių  Bokmål

Bokmål  Slovenčina

Slovenčina  Slovenščina

Slovenščina  Ελληνικά

Ελληνικά  Magyar

Magyar  עברית

עברית