- industrial air compressor

- desiccant compressed air dryer

- diesel air compressor

- large vacuum pump

- oil free piston air compressor

- oil free screw air compressor

- oil free scroll air compressor

- pm vsd dual stage screw air compressor

- pm vsd single stage screw air compressor

- refrigerated air dryer

- screw blower

- single stage double screw air compressor

- two stage double screw air compressor

- ultra high pressure air compressor

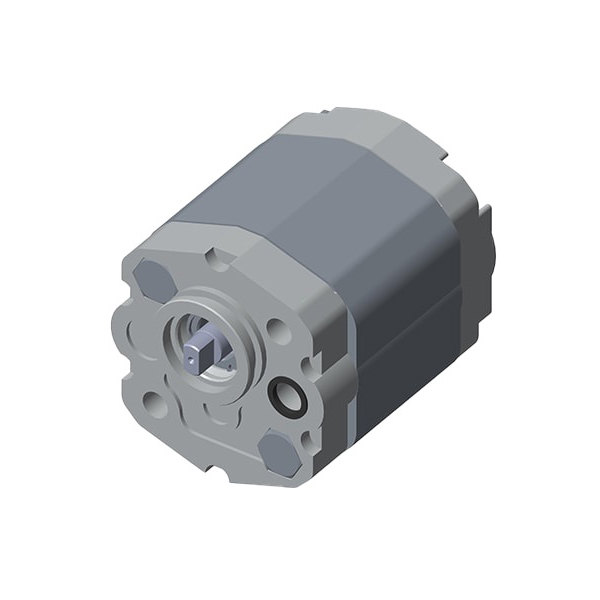

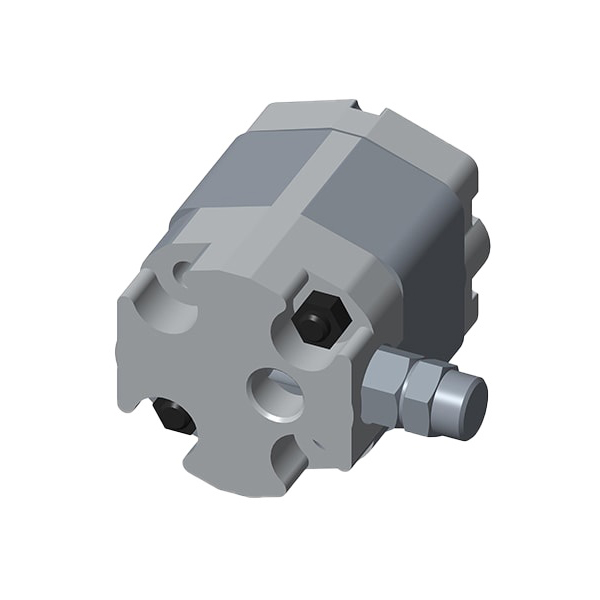

hydraulic gear pumps with built-in relief valve

Hydraulic gear pump is a kind of fluid mechanical equipment that conveys liquid from inlet to outlet through rotating gears. It is widely used in hydraulic systems, mechanical equipment, automotive and energy industries for its simple structure, high reliability, adaptability and high efficiency.

Description

Hydraulic gear pumps are engineered for reliable, high-performance operation across diverse working environments. Thanks to their precise design, they meet different flow and pressure requirements and can run stably for extended periods. Users can select the ideal model based on displacement, speed, pressure, and other parameters to match specific application needs.

Technical Parameters

- Displacement per revolution: 0.8 – 8 cm³/rev

- Direction of rotation: D (clockwise), S (counterclockwise)

- Minimum speed: 600 – 81,000 rpm

- Maximum speed: 2,100 – 86,000 rpm

- Peak pressure: 200 – 8,270 bar

Application Industries

- Hydraulic systems: Provides pressure oil for motors, cylinders, and other hydraulic actuators, ensuring efficient and reliable power delivery.

- Logistics handling equipment: Powers lifting, pushing, and pulling actions in forklifts and platforms, offering strong and stable support.

- Automobile lifters: Ensures smooth and reliable lifting/lowering in vehicle repair and inspection equipment.

- Wind power generation: Drives wind turbine angle and pitch adjustment with stable high-pressure output, suitable for harsh environments.

Features

- High flow and pressure output: Low energy consumption, efficient working principle, and prolonged pump life.

- Long service life: High-quality materials and precision machining withstand high loads and reduce maintenance costs.

- Stable performance at low speeds: Maintains efficiency and smooth flow, reduces wear, and extends lifespan.

- Versatile ports and shaft extensions: Multiple options for easy integration with different hydraulic systems.

- Leak-free shaft seal: Ensures safety, prevents hydraulic oil waste, and maintains stability under high pressure.

- Built-in relief valve: Protects the system from overload by automatic pressure unloading, safeguarding key components.

- High/low pressure options: Choose based on specific requirements—high pressure for heavy machinery, low pressure for fluid transfer.

English

English  Français

Français  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  Türkçe

Türkçe  Svenska

Svenska  Polski

Polski  Română

Română  Latviešu

Latviešu  한국어

한국어  Русский

Русский  Español

Español  Deutsch

Deutsch  Українська

Українська  Português

Português  العربية

العربية  Indonesian

Indonesian  Čeština

Čeština  Suomi

Suomi  Eesti

Eesti  Български

Български  Dansk

Dansk  Lietuvių

Lietuvių  Bokmål

Bokmål  Slovenčina

Slovenčina  Slovenščina

Slovenščina  Ελληνικά

Ελληνικά  Magyar

Magyar  עברית

עברית