- industrial air compressor

- desiccant compressed air dryer

- diesel air compressor

- large vacuum pump

- oil free piston air compressor

- oil free screw air compressor

- oil free scroll air compressor

- pm vsd dual stage screw air compressor

- pm vsd single stage screw air compressor

- refrigerated air dryer

- screw blower

- single stage double screw air compressor

- two stage double screw air compressor

- ultra high pressure air compressor

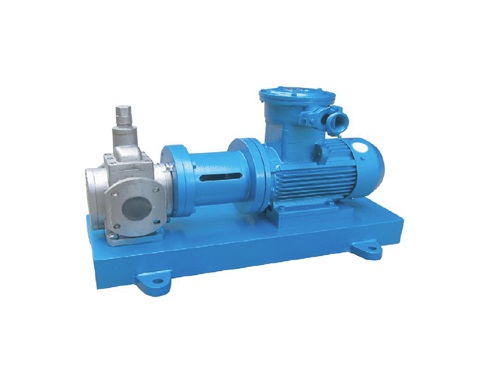

magnetic gear pump which is 316L titanium or other metal

Through its simple and efficient structural design, the direct-connected metal magnetic gear pump is suitable for a variety of application scenarios of conveying viscosity, organic chemical media.

Description

The stainless steel 316L magnetic gear pump is designed for the reliable transfer of high-viscosity organic chemical media. Built to ISO2858 standards with fluid-contact parts crafted from 304, 316, 316L stainless steel, titanium, and other corrosion-resistant metals, it features a direct-connected structure for maximum efficiency and compactness.

Performance

- Flow rate: 0.6–40 m³/h

- Head: 60 m

- Maximum operating temperature: 300°C

- Withstanding pressure: 1.6 MPa

Applications

- Chemical industry: Resins, emulsions, solvents, high-viscosity liquids

- Petroleum industry: Crude oil, lubricating oils requiring high pressure

- Pharmaceutical industry: High-viscosity drug solutions, emulsions, chemical reagents

- Food & beverage: Syrups, honey, jams, and other high-viscosity fluids

- Environmental protection: Waste liquid transport, especially for high-viscosity and corrosive liquids

Key Features & Advantages

- Small flow, high head: Designed for applications requiring steady, high-pressure delivery of viscous media.

- Magnetic drive: Magnetic coupling eliminates mechanical seals, preventing leakage and wear—ideal for toxic, hazardous, or valuable fluids.

- Hastelloy isolation sleeve: Superior resistance to corrosion and high temperatures, ensuring stable, long-lasting operation in demanding conditions.

- Impeller polishing technology: Minimizes friction and energy loss, improving pump efficiency and operational stability.

- Direct-connected structure: Compact design with fewer points of failure and simplified maintenance; intermediate coupling can be added for high-temperature media.

Working Principle

The magnetic gear pump operates by rotating gears within the pump body, powered via a magnetic coupling system. The magnetic field drives the gears to create a sealed chamber, drawing in and pushing liquid to the outlet. The direct connection provides a simplified and robust structure, while the magnetic drive ensures leak-free, reliable performance without mechanical contact.

Summary

Magnetic gear pumps excel in handling high-pressure, high-viscosity, and high-temperature fluids across chemical, petroleum, pharmaceutical, food, and environmental industries. Features like Hastelloy isolation sleeves and impeller polishing technology further enhance performance and longevity in corrosive and demanding conditions.

English

English  Français

Français  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  Türkçe

Türkçe  Svenska

Svenska  Polski

Polski  Română

Română  Latviešu

Latviešu  한국어

한국어  Русский

Русский  Español

Español  Deutsch

Deutsch  Українська

Українська  Português

Português  العربية

العربية  Indonesian

Indonesian  Čeština

Čeština  Suomi

Suomi  Eesti

Eesti  Български

Български  Dansk

Dansk  Lietuvių

Lietuvių  Bokmål

Bokmål  Slovenčina

Slovenčina  Slovenščina

Slovenščina  Ελληνικά

Ελληνικά  Magyar

Magyar  עברית

עברית