- industrial air compressor

- desiccant compressed air dryer

- diesel air compressor

- large vacuum pump

- oil free piston air compressor

- oil free screw air compressor

- oil free scroll air compressor

- pm vsd dual stage screw air compressor

- pm vsd single stage screw air compressor

- refrigerated air dryer

- screw blower

- single stage double screw air compressor

- two stage double screw air compressor

- ultra high pressure air compressor

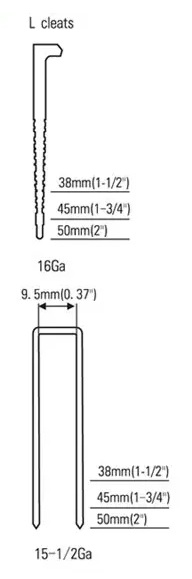

pneumatic flooring nailer for installation of wood floors

pneumatic flooring nailer is a specially designed for fast, accurate installation of flooring pneumatic tools, widely used in artificial flooring, solid wood flooring, hardwood flooring and bamboo flooring construction.

Description

Pneumatic flooring nailer can effectively reduce the gap between the boards and significantly improve the work efficiency, widely used in residential and commercial buildings floor laying work.

Features of Pneumatic Flooring Nailer

- High-speed design: Utilizes high-speed pneumatic technology to quickly complete large areas of floor laying, effectively eliminating gaps between flooring boards for a tight, high-quality installation.

- Sturdy engineering plastic handle and lightweight die-casting body: Ergonomically designed handle offers comfort, impact resistance, and wear resistance; lightweight die-casting body reduces tool weight, minimizing user fatigue during prolonged use.

- Mallet Pneumatic Drive: The mallet drive system uses air pressure to push the striking bar, enabling quick and accurate nailing into flooring material while protecting the baseboard from wear to keep floors intact.

- Low Air Consumption Design: Consumes only 3.5 SCFM of air, saving air pressure resources compared to traditional tools for more economical and efficient operation.

- Interchangeable base plate: Easily adjustable base plate adapts to different flooring materials, ensuring efficiency and versatility for various installation needs.

Working Principle of Pneumatic Flooring Nailer

The pneumatic flooring nailer operates using a pneumatic drive system. When triggered, compressed air from a gas compressor enters the nailer body, activating internal pneumatic components. The mallet drive system rapidly pushes the piston, driving nails through the nailer head at a precise angle and force into the flooring material. This ensures consistent nail depth and prevents damage to the floor. The low air consumption design further enhances efficiency and allows for stable operation over extended periods.

Application Areas of Pneumatic Flooring Nailer

- Artificial flooring installation: Provides strong fixation for composite flooring in residential and commercial spaces, ensuring solid joints and an enhanced ground effect.

- Solid wood flooring installation: Accurately drives nails without damaging natural wood, maintaining secure and stable installation for high-end homes.

- Hardwood flooring installation: Delivers high-precision nailing for hard and wear-resistant flooring, preserving surface quality during efficient laying.

- Bamboo flooring: Offers precise nail penetration for bamboo floors, ensuring beauty, strength, and durability after installation.

English

English  Français

Français  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  Türkçe

Türkçe  Svenska

Svenska  Polski

Polski  Română

Română  Latviešu

Latviešu  한국어

한국어  Русский

Русский  Español

Español  Deutsch

Deutsch  Українська

Українська  Português

Português  العربية

العربية  Indonesian

Indonesian  Čeština

Čeština  Suomi

Suomi  Eesti

Eesti  Български

Български  Dansk

Dansk  Lietuvių

Lietuvių  Bokmål

Bokmål  Slovenčina

Slovenčina  Slovenščina

Slovenščina  Ελληνικά

Ελληνικά  Magyar

Magyar  עברית

עברית