- industrial air compressor

- desiccant compressed air dryer

- diesel air compressor

- large vacuum pump

- oil free piston air compressor

- oil free screw air compressor

- oil free scroll air compressor

- pm vsd dual stage screw air compressor

- pm vsd single stage screw air compressor

- refrigerated air dryer

- screw blower

- single stage double screw air compressor

- two stage double screw air compressor

- ultra high pressure air compressor

pneumatic medimu crown stapler for furniture reinforcement

Pneumatic medimu crown stapler is a professional-grade pneumatic tool designed for medium and heavy assembly tasks, widely used in structural connections, cabinet making, wood component reinforcement and other high-strength nailing occasions.

Description

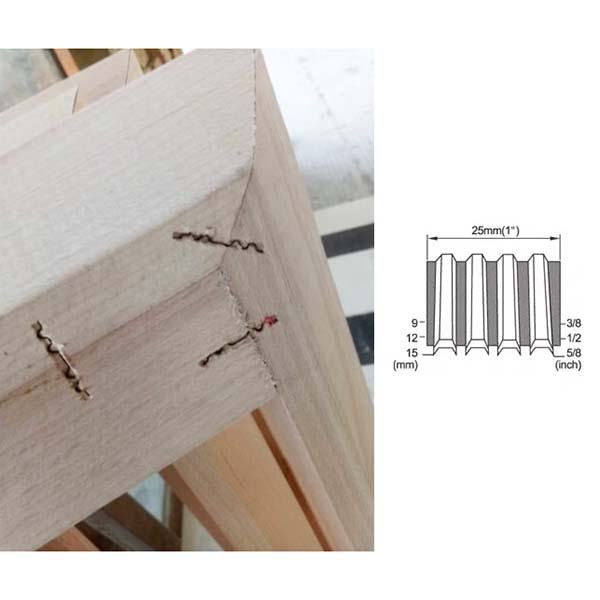

Pneumatic medimu crown stapler adopts wave nails, commonly known as wave nails, with excellent tensile properties and structural stability, suitable for industrial use with high requirements on bonding strength.

The body size is 99×270×310mm, net weight 2.9kg, with 8mm air hose interface, to ensure that in the high-intensity nailing operations can still maintain a strong and stable nail force, can be used in carpentry shops, furniture factories and assembly lines.

Technical Parameters of Pneumatic Medimu Crown Stapler

- Order No.: CF15

- Weight: 2.9kg

- Size: 99x270x310mm

- Number of nails: 100 pieces

- Air pressure: 5 to 7kg/cm²

- Diameter of air tube: 8mm

- Use: Structural jointing, assembling cabinets, etc.

Features of Pneumatic Medimu Crown Stapler

- High-strength structural design: The body is made of industrial-grade alloy material, sturdy and durable, suitable for high-frequency continuous operation.

- Powerful nail hitting force: Working air pressure range of 5 ~ 7kg/cm², providing stable and strong power output, to ensure that the wave nails are firmly embedded in hard wood or composite materials.

- Ripple nails strong stability: Wave nail design is “wave” shape, embedded in the wood bite stronger, anti-loosening ability far more than straight nails, suitable for load-bearing structure fixing.

- Large nail compartment capacity: Can be loaded with 100 pieces of ripple nails, reducing the frequency of adding nails, enhance the efficiency of continuous operation.

- Ergonomic design: Handle non-slip rubberized design, balanced center of gravity arrangement, enhance the comfort and stability of long-term use.

- High safety performance: With a safety switch system, to avoid accidental contact with the nail caused by accidents.

Pneumatic Medimu Crown Stapler Working Principle Description

- Gas supply stage: Connected to the external air compression system, through the 8mm gas pipe will be introduced into the medimu crown stapler body gas storage chamber.

- Trigger stage: The operator presses the trigger, the valve opens quickly, the compressed air into the main cylinder.

- Drive stage: The gas pushes the piston down quickly, driving the firing pin to hit the nail piece, the corrugated nails will be strong shot into the material to be fixed.

- Exhaust reset: After the trigger is released, the system quickly exhaust, spring or air pressure to help make the piston reset, ready for the next action.

Wave nail itself is wave-shaped, both sides of the hook tooth-like edge, can bite the material like a sawtooth, hit into not easy to pull out, even under severe vibration is still maintaining a solid structure.

Analysis of the Application Areas of Pneumatic Medimu Crown Stapler

- The overall cabinet manufacturing: Used to fix the cabinet side panels, back panels, compartments between the skeleton structure, to improve the overall load-bearing capacity and stability.

- Furniture reinforcement and assembly: For solid wood furniture, composite board furniture splicing at the structure of the fixed, such as bed frame, closet, TV cabinet.

- Woodworking structure connection: Wood house, wood platform, woodworking exhibition frame and other structures of the rapid assembly, especially in the site construction, exhibition props and other on-site assembly has great use.

- Industrial Packaging Reinforcement: Bite type reinforcement for heavy wooden packaging boxes and transportation pallets to enhance the overall compressive and seismic performance.

- Building decoration: Roof beams, wooden flooring, ceiling keel and other projects, for high-strength plates and wood components between the connection.

English

English  Français

Français  Tiếng Việt

Tiếng Việt  Italiano

Italiano  Nederlands

Nederlands  Türkçe

Türkçe  Svenska

Svenska  Polski

Polski  Română

Română  Latviešu

Latviešu  한국어

한국어  Русский

Русский  Español

Español  Deutsch

Deutsch  Українська

Українська  Português

Português  العربية

العربية  Indonesian

Indonesian  Čeština

Čeština  Suomi

Suomi  Eesti

Eesti  Български

Български  Dansk

Dansk  Lietuvių

Lietuvių  Bokmål

Bokmål  Slovenčina

Slovenčina  Slovenščina

Slovenščina  Ελληνικά

Ελληνικά  Magyar

Magyar  עברית

עברית